Historically, conveyor operators have been limited to using excessive soap and water to reach the performance levels needed to meet their production goals. Considering the numerous drawbacks of using soap and water for lubrication, many manufacturers have moved to using precise amounts of dry lubricant instead. While dry lubrication does reduce water usage, it can also…

Read More >>Versatile VRC Improves Efficiency and Prioritizes Worker Safety PFlow Industries, the pioneer in vertical reciprocating conveyor (VRC) technology, highlights the 21 Series Hydraulic Vertical Lift, an ideal solution for material lifting needs in a variety of applications. Engineered to meet the diverse material handling needs of various industries, the 21 Series offers unparalleled versatility, efficiency,…

Read More >>… including full transport conveyance from pasteurizer to case packer. Multi-Conveyor was recently requested to build a series of conveyors to transport and accumulate a ‘bourbon shine’ inspired beverage for a start-up distillery in the Smokey Mountain foothills. A variety of conveyor technologies were implemented to smoothly transport beverage cans between different processing machines in…

Read More >>… sounds like an oxymoron, but it’s not. Multi-Conveyor recently built a series of conveyor technologies designed to tactically transport a granulated or whole bean dry beverage product. Product travels from two bagger discharges, though curves and elevations, ultimately depositing onto a continuous running loop where it is staged for hand-packing. (Note: Product used in…

Read More >>Dorner, a pioneer in conveyor technology, is proud to introduce DualMove. This product excels in many applications, including – but not limited to – electronics, appliances, automotive, and battery production. Joining Dorner’s collection of innovative pallet systems, the DualMove utilizes twin-strand timing belts to precisely place, orientate, and transfer pallets to workstations for robotic or…

Read More >>The food-grade Slim-Fit is the newest line of low profile, wash down, sanitary conveyor belts from Multi-Conveyor. Featuring tool-less belt removal, the pre-engineered small product transfer conveyor is designed for tight spaces, and features 100% stainless steel, 3-ply blue wash down belting and easy tool-less belt removal. “The Slim Fit sanitary conveyor is becoming the…

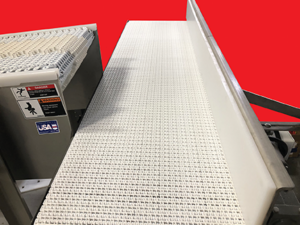

Read More >>In addition to custom conveyor systems, Multi-Conveyor builds basic, quick-ship plastic chain conveyors by the mile. These modular systems are designed to be pieced together fast, and are available in various pre-fabricated lengths, widths or radius curves. “Although we’re a conveyor manufacturer known for our custom conveyor solutions, our standard conveyors are probably the most economical, quick-ship…

Read More >>Force Control Industries MagnaShear™ motor brakes are maintenance-free, and require no-adjustment, so they virtually eliminate motor brake downtime and maintenance costs. The resulting increase in production time can bolster productivity, efficiency, and profitability for manufacturing plants of all types. With no adjustment or maintenance required, save for an annual oil change, these dependable motor brakes…

Read More >>PharmafillTM Conveyors Roll Up to Line, Roll from One Line to Another CV Series conveyors in the PharmafillTM line from packaging machinery manufacturer Deitz Co., Wall, NJ (www.Deitzco.com), feature optional casters or floor levelers as standard. Offered as an added convenience, the non-marking, swiveling, locking casters enable packaging engineers and line operators to roll the…

Read More >>A newly released report details the current state of conveying systems in the food and beverage industry, providing processors with critical data to make informed decisions To provide food processors with insight into the industry’s current challenges and opportunities, Cablevey Conveyors, a global specialty conveyor manufacturer, and Automated Handling Solutions, a service-focused subsidiary of Cablevey,…

Read More >>Multi-Conveyor recently built a food-grade transport conveyor system consisting of two levels of sanitary compliance. The initial conveyors are stainless steel constructed for maximum 3A Dairy compliance as required to move processed cheese in a food-grade, wash-down atmosphere through the bagging process. The filled bags then travel through a sectional wall, into a reduced sanitation…

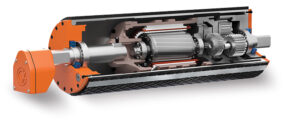

Read More >>How Engineers Eliminated Heat Issues By Alexander Kanaris, Founder and President of VDG (Van der Graaf) The drum motor, used to power conveyor belts since the 1950s, operates safely and is often a space saver. But they haven’t gained traction with the belt conveyor industry because the internally powered conveyor drives tended to overheat. But…

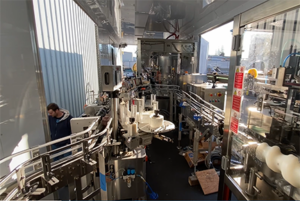

Read More >>… from vineyard to packed cases of wine. Multi-Conveyor was approached by a reputable wine industry integrator in search of complex conveyor engineering. Our team of decades-experienced engineers were the only conveyor manufacturer willing to take on that challenge – and it paid off. This is the second of two mobile bottling lines for the…

Read More >>If you are looking for a sure bet in Las Vegas, it’s the AquaGard GT, a new conveyor system that combines the strengths of Dorner and Garvey®, both Columbus McKinnon brands. The AquaGard GT leads an impressive lineup of conveyors in action in booth C-1455 at PACK EXPO 2023, September 11-13, at the Las Vegas Convention…

Read More >>Multi-Conveyor will have many conveyor technologies on display at Pack Expo Las Vegas with the claim of reviewing all of them in less than 30 seconds! The theme, “give us 30 seconds”, goes hand-in-hand with our touchless “scan & go” technology downloads and our 25-second “everything we make” video. Running on the show floor will…

Read More >>Intuitive Conveyor Systems Are Key in the Packaging Line of the Future By Marco Pardo, a product manager at Dorner With all the talk of automation, e-commerce and other trends in modern packaging, the “middleman” role played by conveyors at times may not seem like a top priority. However, a solid, precise, intuitive conveyor system…

Read More >>Stainless Steel: an Ideal Conveyor Material for Specialty Food Packaging Applications By Denis Gagnon, CEO of Belt Technologies, Inc. Conveyor belts can be made of a variety of materials, including solid stainless steel, metal mesh, plastic and fabric—but not all belt materials are created equal. Due to the hygienic nature of the products they handle,…

Read More >>When it comes to the automated and highly efficient packaging of very flat or light products in film pouches, MULTIVAC has modified its B 625 chamber belt machine in such a way, that a sealing height of 0 mm is now possible on this proven model, which is designed to pack large batches of product.…

Read More >>… including 90° curves, portability and wash down ready! Multi-Conveyor recently built a system that transports bagged food products through from one to two lanes of travel. The system features a 2-position manual divert gate and a single pin-pull interlock release that allows disconnect of a portable conveyor for relocation. The fixed position 8” wide…

Read More >>Almost two years ago, Ryson was acquired by the Dutch company Royal Apollo Group and the rebranding effort is to closer align the entire group. How does this benefit Ryson and our customers? From the beginning, Ryson has always been a sister company with Royal Apollo Group. We have pooled resources, engineering, and manufacturing techniques.…

Read More >>