Search results for: multi-conveyor

Metered Merge with Manual Lift Gates

Multi-Conveyor recently built a series of powered plastic chain conveyors that incorporate manual lift gates for operator access, and pneumatic stop/clamp control for seamless merge. The overall project merges two lines fed from two existing case packers down to a single lane prior to the customer’s case sealer and ultimate palletizer. Slightly inclined, offset conveyors…

Read MorePassive Transfers Facilitate Multiple Side Case Printing

… without elaborate pneumatics or controls and NO pinch points! Multi-Conveyor recently built three mild-steel constructed conveyors that passive off transfer from narrow to wide side leading (and back) to facilitate multiple side case printing. The cases start narrow side leading then transfer 90 degrees to wide side leading without using pneumatic pushers or elaborate…

Read MorePrecision Timed Hand Pack with Semi-Automated Indexing Feeds Labelers and Metal Detectors with Room to Grow

Multi-Conveyor recently built multiple sanitary, precision timed, semi-automatic hand pack conveyor lines that ultimately feed labelers and metal detection systems. Six straight running plastic belt conveyors could allow a customer supplied tray denesting machine to dispense single lane empty plastic food trays onto an indexing conveyor where operators manually fill. Sensors are provided for tray…

Read MoreCleated Incline Slider-Bed Trough Conveyor

Multi-Conveyor recently built a stainless steel constructed cleated incline trough-style belt conveyor designed to transport product waste to a customer supplied hopper. The 24 in. wide belts feature 2 in. high flights every 8 in. that capture and incline the debris up to 50 in. on the incline. The product releases through a series of…

Read MoreMetered High-Speed Servo Conveyors

Multi-Conveyor recently built this metered servo merge conveyor as part of a larger system to transport packaged food. The metering conveyor feeds a series of servo belt conveyors to gap two lanes of product into a single lane flow using DARB technology. A series of photo-sensors were reportedly placed to sense product for the precise…

Read MoreElevated Conveyor Maximizes Production

Multi-Conveyor announced it recently built a conveyor system to transport bags of sugar from three separate bag filling machines to ultimately feed a robotic tray packer. The filled bags exit the bagging machines standing upright with the narrow edge leading. Three lanes merge into one, with a pneumatic traffic cop gate system. Once single filed,…

Read MoreMassive Bi-Directional Accumulation For Super High-Speed Filling

Multi-Conveyor recently modified the layout of a high-speed canning line by adding intermediate sections and adding a massive stainless steel bi-directional accumulation table. The modification included a 51′ mass flow transport conveyor section and a 54′ long by 10’ wide accumulation table to hold backed-up or accumulated product to nearly 14,000 cans at a required…

Read MoreZ-Incline Elevates IQF 14 Feet

Multi-Conveyor recently built a stainless steel vertical scoop flight elevator that raises fresh frozen fruit over 14 ft. in a small footprint. The operator manually loads bulk individually quick frozen (IQF) product into a specially designed infeed hopper where it will accumulate until the conveyor can take it away. The product inclines and then discharges…

Read MorePallet Unloading Conveyor

Multi-Conveyor recently built a 48 in. wide stainless steel constructed chain conveyor system to move both empty and full pallets over seven separate conveyor sections totaling over 40 feet of over-under conveyance. Operators load full pallets onto the upper level where the pallet advances through two staging zones, controlled by photo-eyes, to the unloading zone.…

Read MoreOverhead Conveyor Feeds Decline Drum Rotary Spiral Conveyor

Overhead table top plastic chain accepts single file product from a customer supplied discharging de-palletizing machine.

Read MoreGetting Creative with a Conveyor

As smaller packaging manufacturers enter the market, conveyor systems designed to increase efficiency and make use of smaller spaces are more in demand. By Christine Pietryla Wetzler We all know that conveyors “convey” items from one point to another in a packaging operation. However simple the product may be, the industry is becoming more complex…

Read MoreAlpine Accumulation Defers Product Up to 4 Minutes of Off-Line Production

Multi-Conveyor recently built this single lane, off-line accumulation, space-saving, Alpine-style conveyor to detect and accept various sizes of bottled salad dressings.

Read MoreElectrical Controls, VFD’s, Servos, Photo Eyes and More

Multi-Conveyor has decades of combined controls experience. Multi-Conveyor’s electrical team has built simplistic, standard powered equipment as well as complete, intricately controlled systems for the most complicated conveyor operation or integration. This newly released video will briefly show how an electrical panel the size of a garage door, is actually built. We start with UL…

Read MoreConveyors: The Ins and Outs

Which Type Is Best for Your Application, And What You Should Consider When Making A Purchase. By: Elisabeth Cuneo, Editor Conveying and accumulation are both so critical to the packaging line, as conveyors move product from one spot on the line to the next, and accumulation can account for machine operation downtimes When looking to…

Read MoreNewly Released Video: Upender Conveyor Technology

Multi-Conveyor (multi-conveyor.com) recently built this stainless steel table top system designed to rotate bag-in-box cartons from wide edge to narrow edge leading using simple gravity with minimal guidance for reorientation. A single lane slave driven timing belt supports cartons on the right-hand side allowing the bottom of the cartons to rotate down counter-clockwise to a…

Read MoreSuper Sanitary Extend and Retract Conveyor

Winneconne, WI – Multi-Conveyor (www.multi-conveyor.com) – Multi-Conveyor recently provided a single stainless steel constructed, pneumatic controlled sanitary quick release tool-less belt conveyor for transporting temperature controlled raw meat product at a volume of more than 50,000 lbs per hour. The conveyor has a retractable idle and drive end with a center take-up. The retractable idle…

Read MoreSimultaneous Release 2:1 Merge for Bagged Products

Winneconne, WI – Multi-Conveyor (http://www.multi-conveyor.com/) – Multi-Conveyor was recently challenged to merge two lanes of separately fed 12” long bagged food products that needed to merge into a single lane at 110 products per minute. The initial multiple servo solution would have exceeded the customer’s overall budget so Multi-Conveyor’s design team got to work to…

Read MoreRotary Tables for Pharmaceutical Application

Winneconne, WI – Multi-Conveyor (http://www.multi-conveyor.com/) – Multi- Conveyor recently built two 48″ diameter 11 gauge Stainless Steel Rotary Tables for a pharmaceutical application. The table easily adapts to varying sizes and shape products showing the versatility of these systems for many applications. This particular project will be accumulating bottles from 1 to 4 inches square…

Read MoreHigh Speed Single Filer with Multiple 900 Transfers

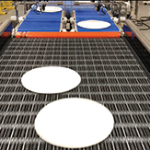

One of our smallest footprint transfer systems! Winneconne, WI – Multi-Conveyor (http://www.multi-conveyor.com/) – Multi-Conveyor’s engineers have developed one of our smallest footprint, single-filing systems for low profile objects. This engineered solution demonstrates how a small height, circular product can move accurately through extremely fast-paced 90° conveyor transfers. With products as incredibly small in diameter as…

Read MoreAsynchronous deposited bag conveyor doubles products per minute

This system tackles both speed and position control – very cool. Winneconne, WI – Multi-Conveyor (http://www.multi-conveyor.com/) – Multi-Conveyor has just built this 2:1 mild steel constructed conveyor system that merges over 100 products per minute from two lines into a single line (doubling the product/minute production rate) to feed an automated case packing machine. Individual…

Read More