How to Improve Case Sealing Operations

To increase uptime, boost efficiency and reduce waste, your partner’s ability to collaborate, implement and support your needs is key. Image courtesy of Shurtape Technologies LLC.

Picking the Right Packaging Partner is Essential

By Bradley Dunlap, Director of Product Marketing, Industrial Packaging at Shurtape Technologies, LLC

Whether you are a consumer packaged goods operations manager or a packaging line engineer, finding the right packaging partner for your case sealing operation is essential for increasing uptime, improving efficiency and reducing product damage and loss. These benefits can also enhance customer satisfaction and attract new customers to increase profitability.

Finding a partner who can help you accomplish all of this while keeping current operations profitable may seem daunting. Here are three key qualities to look for that will help ensure success.

- Auditing and custom solutions. While many case sealing operations are highly systematized, each is unique and has its own challenges. An off-the-shelf case sealing solution may be the best fit, but before pushing products, a good packaging partner will conduct an audit of your case sealing operation and consult with you about pain points. A thorough audit performed by an experienced packaging professional considers every facet of your case sealing operation, from equipment and personnel to warehousing conditions and downstream handling.

Each of these elements contributes information essential for designing and optimizing your particular solution. A reliable packaging partner will capture these details and review them with you before recommending tapes or tape applicators.

- Assistance with implementation. Uptime is essential to maintaining profitability, and finding a packaging partner who provides support during the implementation phase of their products or equipment is crucial to protecting that uptime.

When starting with a new automated system, tape applicator or carton sealing tape, you are the expert in your operation, while your packaging partner should be the expert in the solution. You understand how your equipment operates, how your personnel perform and how they come together to create the workflow. Your partner should understand where and how to fit their products, equipment and tech support into the workflow with minimal disruption. Your partner should also be on site during implementation to train your personnel on tasks like changeovers, provide basic troubleshooting as needed and address any issues that arise.

- Timely support after the sale. Once you’ve invested in a case sealing solution, your packaging team, your freight carrier and your customers will depend on you to make sure it delivers as promised. Knowing you will receive a rapid response and timely service from your partner if equipment malfunctions or product fails will give you peace of mind that the problem will be quickly resolved and your products will arrive intact.

In the past, it was common to train in-house personnel to maintain, troubleshoot and repair equipment instead of waiting for a specialized technician. Few organizations follow that practice today. Labor shortages have made it difficult to assign these additional responsibilities to limited personnel, and the increasing complexity of equipment and automation of systems has made such training nearly impossible. Having a packaging partner you can count on to deliver their expertise and resolve issues quickly removes this burden from you and your organization.

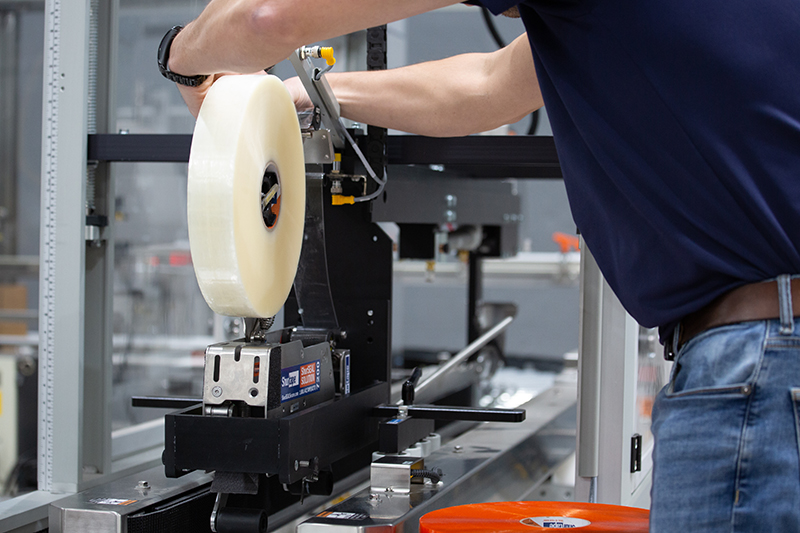

When case sealing equipment breaks down or tape breakage occurs on the packaging line, you need a packaging partner who will help you solve the problem, not one who just sells products. Image courtesy of Shurtape Technologies LLC.

Spotting a Problem Solver

When case sealing equipment breaks down or tape breakage occurs on the packaging line, you need a packaging partner who will help you solve the problem, not one who just sells products. One quick way to assess a partner’s industry knowledge and problem-solving potential is to look at their product line. Their carton sealing tapes should address a full spectrum of applications and consider various factors like carton materials and packaging line conditions. Likewise, tape applicators should be designed to work with the tape products to enhance efficiency.

Examples of the types of case sealing tape products an experienced packaging partner will offer include:

- General purpose hot melt tapes for use with light duty packaging. These tapes are typically rated for application temperatures from about 35 F to 110 F and will stick to a wide range of surfaces.

- Medium duty hot melt tapes for increased packaging weight and greater handling stress. These tapes offer higher bonding strength to maintain carton closure during shipping and handling.

- Heavy duty hot melt tapes for extra heavy, bulky cartons that experience extreme handling. Larger cartons also frequently represent higher value, so these tapes deliver a faster, more aggressive stick and bonding strength to form a more secure and longer-lasting seal.

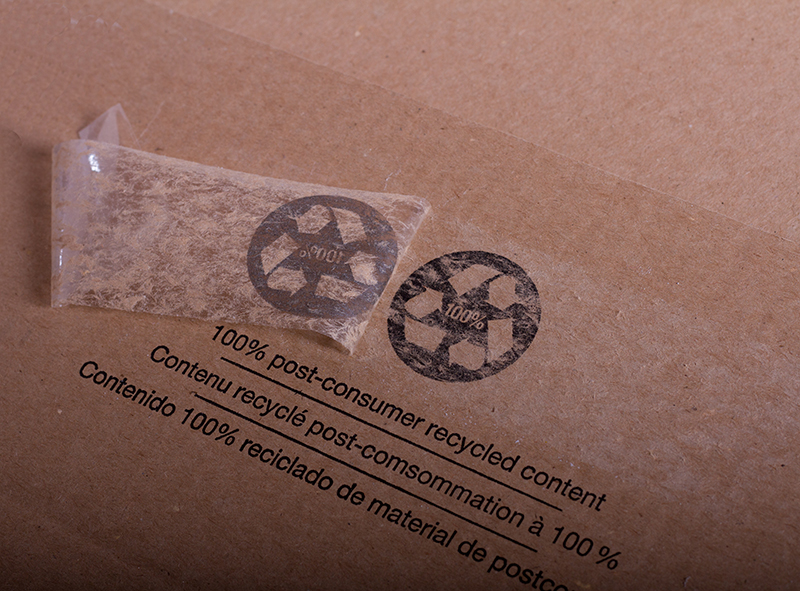

- Specialty tapes for recycled conditions. Sustainability is a key issue in packaging, and cartons are being made with increasing amounts of recycled content. A partner who is on top of the industry will offer hot melt tapes engineered for higher shear, tack and adhesion on highly recycled or even 100 percent recycled cartons.

To put all of this in simple terms, if your potential packaging partner doesn’t offer a tape product that matches your specific case sealing conditions, you should probably keep looking.

Carton sealing tapes should address a full spectrum of applications and consider various factors like carton materials and packaging line conditions. Likewise, tape applicators should be designed to work with the tape products to enhance efficiency. Image courtesy of Shurtape Technologies LLC.

Common issues an experienced partner will understand

Each case sealing operation comes with its own unique challenges, but most can be distilled to a handful of issues that affect nearly every line, including:

- When a tape’s adhesive loses its tack and starts peeling up, it can get caught in the carton sealing equipment as well as further downstream. Cases can also pop open, creating another hazard. These tape failures can result in costly downtime and lost productivity. A proper audit of the packaging environment will point to the problem if your packaging partner knows where to look.

- When a case isn’t sealed correctly, it must be run through the line a second time. Improper sealing can be caused by poor tape adhesion, insufficient applicator pressure or both. An experienced packaging partner will listen to your rework issues, inspect the sealing equipment and tape you are using and help you fix the problem with a properly engineered solution.

- Product damage and loss. When a case seal fails, it creates a series of potentially costly risks, including product damage, contamination, theft and loss. A knowledgeable packaging partner can pinpoint the reason for failure and correct it quickly with the right tape product or applicator.

To measure your packaging partner’s experience level with these issues, check their company website for educational content. Those with a high level of expertise generally like to share their knowledge through tutorials, application stories, blogs and videos. This type of content is great for vetting your partner and can also be helpful for learning about products and solutions that are new to you.

Collaboration and trust yields success

Increasing the uptime and efficiency of your case sealing operation while reducing waste and product loss relies on a packaging partner who will collaborate with you to create a custom solution, assist with implementation and provide long-term support.

Ultimately, you need to trust your packaging partner, so that you can focus on customer satisfaction and profits and not on case sealing tape and equipment.

About the Author

Bradley Dunlap, director of product marketing, industrial packaging, for Shurtape Technologies, LLC, is responsible for leading the product development and marketing support for the Packaging Tape and Equipment category. Learn more at www.shurtape.com.