Cost-effective Handling of Small Parts

New ultra-compact SMS linear modules position small masses accurately and economically, paving the way to electrification.

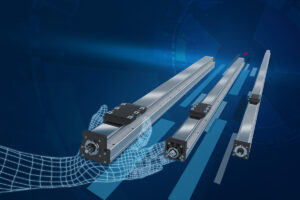

The new linear axes are suitable for handling cost-sensitive small parts and are an alternative to complex pneumatic solutions. (Image source: Bosch Rexroth AG)

Bosch Rexroth has expanded its portfolio of small handling linear axes by adding Small Modules Screw Driven (SMS), the ultra-compact range with ball screw assembly. These particularly low-profile and light linear modules are ideal for simple positioning and feeding tasks and allow economical electrification with a high repeatability. The five predefined sizes from 30 to 120 mm can be selected from the Rexroth online shop. Optional attachment sets for motors from various manufacturers are also available. These help to save even more time during engineering.

The new SMS linear modules are manufactured to the usual Rexroth quality standards. They offer excellent value and a high repeatability of up to ± 0.005 mm. They can be used to position small masses in a wide range of cost-sensitive areas with low to medium dynamics, including the consumer goods and packaging industry, semiconductor and battery production, 3D printing, the automotive sector, medical technology and typical mechanical engineering applications. Thanks to low system and service life costs, the SMS linear modules are also an efficient alternative to pneumatically driven axes.

The electromechanical axes have a compact, low-profile aluminum design with integrated precision guideways. A magnetically fixed steel cover strip protects the components inside. The product range includes five tailored module sizes from 30 to 120 mm for travel ranges of up to 1,200 mm.

The new SMS linear modules can be ordered with no need for additional calculation work via the integrated product selector in the Rexroth online shop. To save even more time during engineering, separate attachment sets for popular servo motors are available – either as a flange coupling or a belt side drive. Customers can also choose from a range of drive controllers and motors from Bosch Rexroth.

About Bosch Rexroth:

As one of the world’s leading suppliers of drive and control technologies, Bosch Rexroth offers its customers hydraulics, electric drive and control technology, gear technology and linear motion and assembly technology, including software and interfaces to the Internet of Things. To learn more, please visit www.boschrexroth.com.

About Bosch:

The Bosch Group is a leading global supplier of technology and services, with innovative solutions for smart homes, Industry 4.0, and connected mobility. Bosch is pursuing a vision of mobility that is sustainable, safe, and exciting. It uses its expertise in sensor technology, software, and services, as well as its own IoT cloud, to offer its customers connected, cross-domain solutions from a single source. The Bosch Group’s strategic objective is to facilitate connected living with products and solutions that either contain artificial intelligence (AI) or have been developed or manufactured with its help. Additional information is available online at www.bosch.com, www.iot.bosch.com, www.bosch-press.com, www.twitter.com/BoschPress.