Metal Detection, X-Ray – or Both?

There are fundamental differences in the ways that metal detection and X-ray inspection technologies work, and it is important to consider the application, physical space and budget. Image courtesy of Mettler-Toledo

How to Choose the Best Technology for Food & Pharma Applications

By Ian Robertshaw, Global Key Account Manager, Mettler-Toledo

Both metal detection and X-ray inspection systems play key roles in product inspection for food and pharmaceutical companies. Choosing the right technology requires consideration of many factors – starting with the application.

A layman might consider it an easy choice: if you are looking for the best inspection technology designed to detect metal contaminants, get a metal detection system. If you are looking for a system to detect both metal and non-metal contaminants, choose the X-ray inspection system.

There is a kernel of accuracy in this supposition, because very often, such as with aluminum and wire, a metal detection system will be better at detecting metal than an X-ray system will. However, the decision is not necessarily so straight forward. For example, what if you do need to identify metal contaminants, but the product is packaged in aluminum foil? The foil is seen as a detectable contaminant by a metal detection system, so it cannot be used. An X-ray system, however, sees straight through the foil to get a better view of a contaminant inside.

Production process considerations

The choice of technology is not simply about the potential type of contaminant that you are looking for; part of the consideration is where in the production process the product should be inspected. For example, if your raw product needs to be inspected before other valuable ingredients are added, maybe a metal detection system is best.

However, for end-of-line inspection when both contaminant detection and packaging integrity checks are required, X-ray technology will be more suitable. What is certain is that product inspection is a critical part of the food production process, ensuring that consumers have confidence in the quality and safety of the products they buy. For food manufacturers, it is important to carefully consider whether to equip their production lines with metal detection or X-ray technology, or perhaps with both.

Consider the application, physical space and budget

There are fundamental differences in the ways that metal detection and X-ray inspection technologies work. It is important for food manufacturers to understand what these differences are and how they can impact the ability to perform optimally on certain product inspection applications.

Application really is the key word here: the nature of the product, the fill process (for example, Vertical Form Fill Seal -VFFS), the potential contaminant types, and factors such as the physical packaging must all be brought into the equation when selecting the right contaminant detection technology. In addition, constraints on finance and physical space, and the range of additional quality control checks should be considered.

Metal detection system capabilities

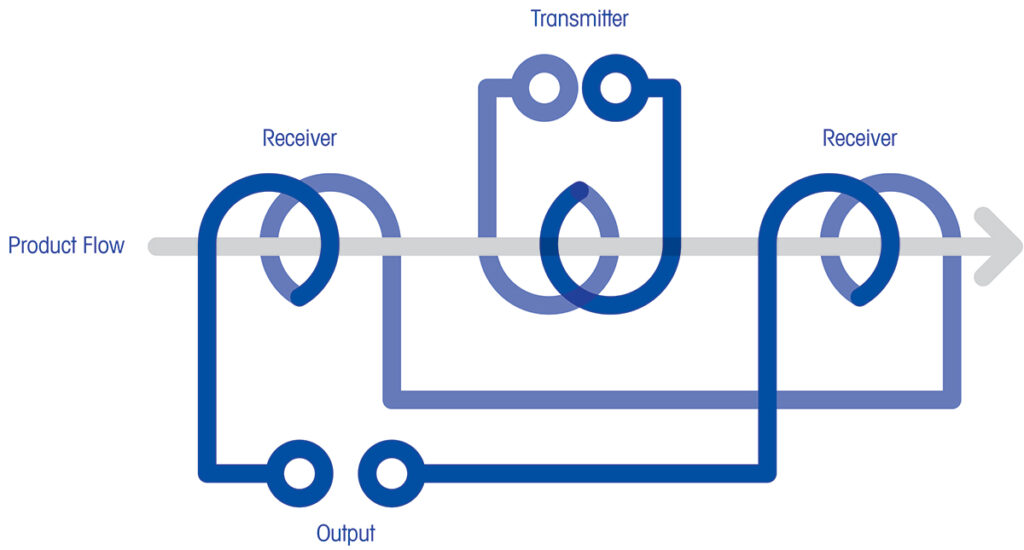

Modern metal detection systems can identify all metals, including ferrous (such as chrome and steel) and non-ferrous (brass and aluminium, for example), as well as both magnetic and non-magnetic stainless steels. They work through a system of coils, charged with an electrical current, to create a balanced electro-magnetic field. If a product passing through this field contains a metal contaminant, the magnetic field is disturbed, and this disturbance is interpreted by sophisticated electronic circuitry and software algorithms.

Modern Metal Detection Systems

Modern metal detection systems create a balanced electro-magnetic field through a system of coils, charged with an electrical current. A disturbance is detected by sophisticated electronic circuitry and software algorithms if metal contaminants pass through the electro-magnetic field. Graphic courtesy of Mettler-Toledo.

A well-designed metal detector for use in the food industry can detect a pinhead in a loaf of bread, while a detector for pharmaceutical applications can detect metal contaminants less than 0.3mm in diameter. In order to perform as these industries demand, the detector construction must be stable and rigid enough to eliminate any movement of the coil system, as even tiny vibrations can cause rejection of perfectly good products. Airborne electrical noise can also be a problem, so it is essential the metal detector is designed to be able to operate reliably in a factory environment.

Consider the ‘product effect’

When it comes to inspection capabilities, metal detection is especially suited to dry products, where the lack of moisture means the product is non-conductive, and therefore does not generate a significant ‘product effect.’ Products with a high moisture content, or those that are salty or acidic, are conductive, as they pass through the metal detector will emit a signal (i.e., the ‘product effect’) that disturbs the detection field.

Product effect is a major consideration, which can lead to high false reject rates. In addition to the moisture or salt content of the product, other factors that contribute to product effect are product temperature, format, consistency, size and shape and orientation on the production line.

Manufacturers can eliminate the impact of product effect by installing a high-quality metal detection system that uses a combination of multi-simultaneous frequency operation and software algorithms to optimize performance and reduce the possibility of costly false rejections. This technology will also result in the system having the right level of sensitivity to pick up signals from very small metal contaminants irrespective of the application and provide the highest level of brand protection.

In addition to packaged products, other applications where metal detection can be used include loose, unpackaged products, pumped products such as liquids, pastes and slurries, bulk powders or free-flowing solids under gravity-fall conditions. In addition, tall, rigid containers such as bottles, jars and composite containers can also be inspected. Although in these applications, inspection would need to take place before a metal cap or closure was applied.

Consider the type of packaging

Metal detectors using multiple frequencies simultaneously or operating at a single low frequency can typically be used with products packed in metalized film packaging, depending on the film thickness. If aluminum foil packaging, such as foil wraps or product trays are used, then the standard balanced coil metal detectors will not be suitable.

A further aspect to consider for both technologies is product size, and we will come to this later.

X-ray inspection capabilities

X-ray inspection systems have the capability to detect a wider range of contaminants than metal detectors, including metal, glass, stone, calcified bone, high-density plastics and rubber. They can also perform a range of additional in-line quality checks, including measuring mass, counting components, identifying missing or broken products, monitoring fill levels, detecting product trapped within the seal, and checking for damaged product and packaging.

The technology works by generating an X-ray beam that passes through a product for inspection and onto a detector. Some of the X-ray beam is absorbed by the product and any contaminant present, and because most contaminants are denser than the products that are being inspected, the contaminants usually absorb more of the X-ray energy.

This difference in absorption becomes apparent in an image generated by the X-ray system, which is then compared to a pre-determined acceptance standard. The product is accepted or rejected based on this comparison. When rejected, the system sends a signal to an automatic reject system, which removes the offending product from the line.

However, while X-ray can easily detect these dense contaminants, with low density contaminants such as insects, wood and polyethylene film, detection by X-ray is not possible.

Nevertheless, X-ray systems can inspect a wide range of different product types, including pumped products such as slurries, fluids and semi-solids, bulk, loose products, jars, bottles and cans, and packaged products, including those packaged in foil or metalized film.

Consider inspection requirements

As we have read, both metal detection systems and X-ray inspection technologies have strengths and weaknesses in the field of product inspection. The process of choosing the right one for this purpose means going back to the application and carrying out a Hazard Analysis and Critical Control Points (HACCP) or Hazard Analysis and Risk-Based Preventive Controls (HARPC) audit.

This will identify what risks of contamination there are with your application, and what types of contamination are likely, as well as providing a greater understanding of the requirements of any customer or compliance related issues.

Critical Control Points (CCPs) should be established to mitigate the risks, and product inspection equipment needs to be installed at these points. If the HACCP/HARPC audit determines that metal is the only likely contaminant, then a metal detection system is probably going to be the best solution.

If metal and/or other contaminants, such as glass, stone or dense plastics are likely to be encountered, then X-ray will be the best solution. However, it is not black and white or a 50/50 decision, as there are many applications where the choice is less clear, and others where the right answer might be to deploy both.

Consider these examples:

Aluminum contaminants in non-metal packaging: as a lightweight, low-density metal, aluminum is hard for X-ray to detect as a contaminant; metal detection is generally the better solution.

Metal contaminants in aluminum foil packaging: metal detection will be unable to spot the contaminants within the foil aluminum unless it is a metalized film; X-ray is generally the better solution.

Metal contaminants in gravity-fed products: X-ray does not work well with falling, accelerating objects that do not have a uniform direction of travel; metal detection is the only viable solution.

Metal contaminants in non-metal packaging: this can be complicated. Metal detection systems are more cost-effective, but if the product is very large, a bigger detector aperture will be needed, which can reduce the sensitivity of the detector. Multi- and high frequency technology can help, but a bigger metal detection system will be required. X-ray power can be increased for larger products, but the cost of installation increases as size increases. If there is a need to protect against non-metallic contamination, the choice will swing towards X-ray.

Non-metal contaminants in any packaging; performing additional quality control issues: X-ray inspection is the only solution, and the additional quality control checks can justify the additional cost of the technology.

Fast/variable line speeds; situations where there is limited space: metal detection (at 400 meters per minute) is able to inspect at faster speeds than X-ray (120 meters per minute), so may have the advantage if other aspects of the application suit metal detection better. Metal detectors are also less space-hungry than X-ray, so depending upon the application, might be more suitable in factories with limited space.

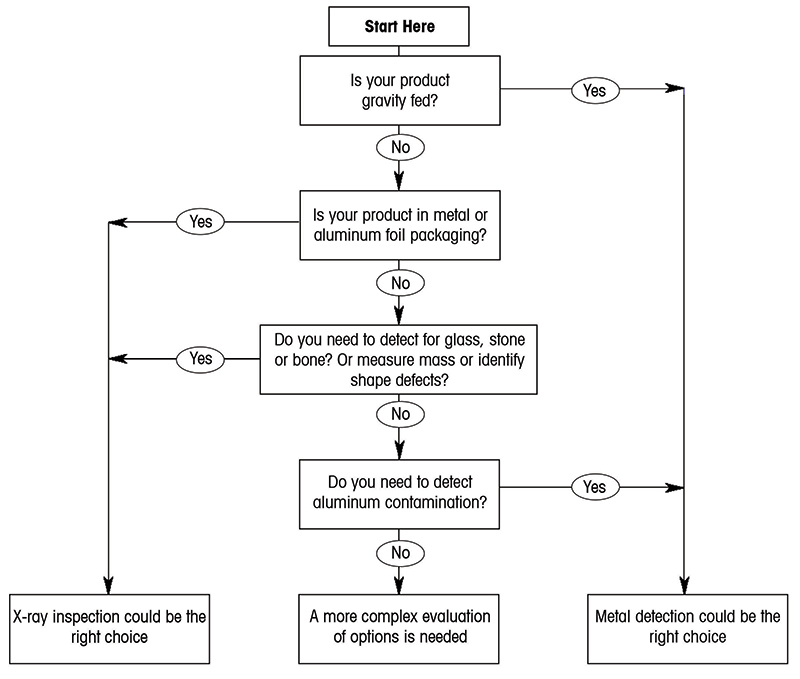

Making it simple

Metal detection or X-ray? The flow chart below is a good starting point for identifying the right answer. However, there is an area of indecision where the application is not packaged in foil and metals other than aluminum are potential contaminants. As the chart shows, in these scenarios a more complex evaluation of options is needed.

The e-Guide, “Metal Detection, X-ray or Both” explains when metal detection or X-ray would be the right choice; or if both solutions should be considered. The free guide is available here. Graphic courtesy of Mettler-Toledo.

There may also be situations in which more than one type of product inspection system is desirable at different CCPs on the production line. For example, it may be wise to install a metal detector early in the processing line to remove large metal contaminants that could, if left present, cause damage to machinery downstream, or fragment into smaller and less easily detectable pieces.

Further down the production line, an X-ray machine could then check for non-metal contaminants as well as perform further quality control checks, while a second and more sensitive metal detection systems at the end-of-the-line could be used to make a final inspection for smaller metal contaminants.

In closing, it is worth reiterating that the first step in choosing a metal detector or an X-ray system for product inspection is to consider the application – the type of product, the type of likely contaminant, and the location of CCPs.

Metal detection offers many advantages for raw product inspection whereas X-ray inspection provides multiple product and packaging integrity checks in addition to contaminant detection. Finally, many additional factors will influence the decision, including space limitations, total cost of ownership, and productivity targets, but the application is where the assessment begins.

About the Author

Ian Robertshaw is a Global Key Account Manager at Mettler-Toledo. To download a free guide explaining how to select the right inspection technology for your project, visit www.mt.com/pi.