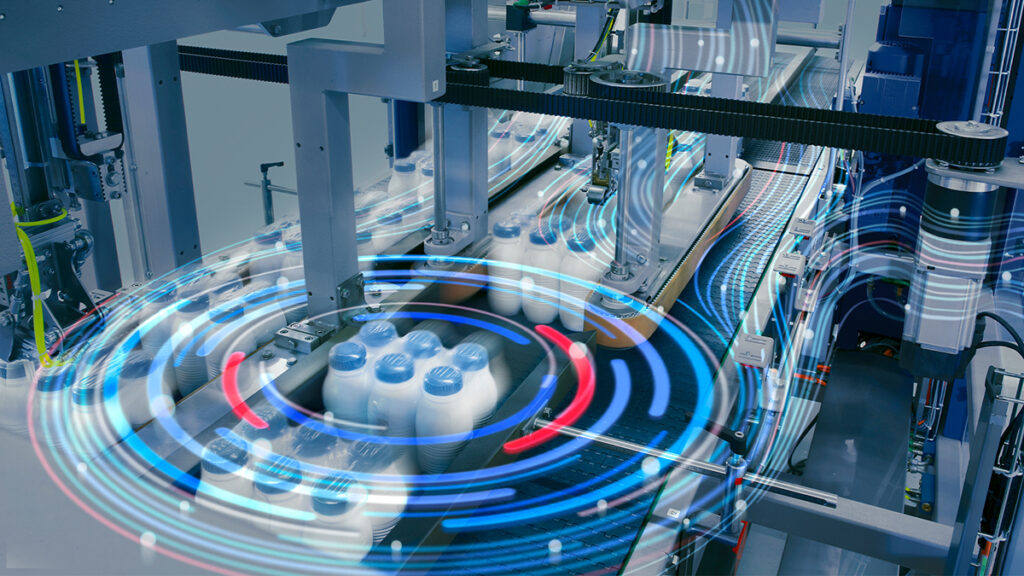

App-based Controls Boost CPG Productivity

Automation suppliers like Bosch Rexroth are introducing new app-based control platforms and other technologies that are easier to use, while offering new capabilities to improve end-of-line packaging line productivity. Image courtesy of Bosch Rexroth.

New Tech Makes Automation More Flexible and Efficient

By Sean Spees, Market Segment Manager for Consumer Packaged Goods at Bosch Rexroth Corporation

Consumer packaged goods (CPG) companies are always striving to increase the efficiency and flexibility of their end-of-line (EOL) operations. But with issues like labor shortages and constantly shifting consumer preferences, it’s difficult for CPGs to achieve these goals. However, automation suppliers are introducing new technologies that are easier to use while offering new capabilities to improve packaging line productivity.

Open, app-based automation controls

A newer approach in automation utilizes an open, app-based control system, similar to how apps are used in the world of IT and smartphones. An app-driven software architecture allows machine builders and packaging line operators to add machine functionality, including from third-party specialists, without the need for complicated programming.

For example, multi-axis handling systems are essential in EOL cartoning systems. These systems are often engineered to particular packaging configurations and dimensions, which means that a new product introduction or change on the line often requires new programming or reconfiguration.

However, with an app-based controls platform, new functionality can be downloaded, tested and integrated into the automation system much faster, with minimal programming and less risk of error and rework.

High-speed/high-capacity conveyors

Packaging operations need reliable, high-throughput conveyors that make it easier to reconfigure EOL process flows as product mix and market demand changes. These systems also need robust components and innovative features to ensure high performance and low maintenance.

Modular plastic chain conveyors offer greater flexibility and reconfigurability to enable packaging companies to handle a wider range of SKUs. Smart connection technology saves time during conveyor assembly and allows for easy conversions and system extensions. These types of conveyors can also reduce floorspace requirements by being configured to travel overhead.

To transport larger capacities and heavier loads, a new generation of linear motor-conveyors now feature individually programmable carriers to provide much greater flexibility in the flow of materials and packages.

Modular plastic chain conveyors like the VarioFlow from Bosch Rexroth offer greater flexibility and reconfigurability to enable packaging companies to handle a wider range of SKUs. Image courtesy of Bosch Rexroth.

Smart mechatronics and material handling

EOL operations often use high-performance mechatronic handling systems like linear robots to pick and place cartons or cases from one line to the next with maximum efficiency. These systems should be easily customized, and reconfigurable as new products and packaging requirements are introduced.

CPGs should consider using new plug-and-play smart mechatronics systems for handling applications. These new systems take advantage of online e-tools that support simple and fast component selection and configuration of multi-axis systems with minimal programming.

The system is ordered and delivered as one package (making it easier for procurement), with preinstalled software for fast commissioning. This same software also supports easier reconfiguration of handling sequences by EOL operators, rather than requiring specialized programmers.

Along with these technologies, new platforms such as autonomous mobile robots and cobots can also help improve EOL flexibility and productivity.

Selecting a supplier

Finally, as you consider how to implement new automation platforms, it’s important to work with an experienced technology supplier that can provide these capabilities all under one roof. This gives you more flexibility to address specific applications while still ensuring components work together for more complete and fully integrated EOL solutions.

About the Author

Sean Spees is the Market Segment Manager for Consumer Packaged Goods at Bosch Rexroth Corporation. He leads a team of solution architects and business development managers to provide complete automation solutions for end users, original equipment manufacturers and systems integrators. Learn more at www.boschrexroth-us.com/cpg-info.