The Packaging Strategy Everyone Should Know

Automating e-commerce operations provides a path for growth by adding speed and accuracy

By David Nettles, Director of Sales, Texwrap Packaging Systems

Effectively managing a business’s e-commerce operation can be challenging, especially when it comes to the packaging process.

Effectively managing a business’s e-commerce operation can be challenging, especially when it comes to the packaging process.

For many companies, e-commerce packaging is a labor-intensive endeavor that is not a very efficient operation. As the retail industry continues to evolve, companies are shipping direct to consumers more than ever before. This shift in retail buying patterns shows no sign of slowing down.

According to Statista.com, a business data platform that specializes in market and consumer data, e-commerce sales in the United States accounted for 13.3% of all retail sales for the second quarter of 2021, which represents an increase of 2.5% from the same quarter just two years ago. Similar trends are seen worldwide, as e-commerce sales that accounted for $4.28 trillion in 2020 are expected to grow to $5.4 trillion by 2022.

The key for many companies growing their e-commerce operation is to select partners that have deep application knowledge and proven solutions. Possessing that type of industry insight can be the catalyst to help companies automate their e-commerce packaging processes to reduce labor, minimize material usage and control their shipping expenses.

The value of automated e-commerce packaging operations

For some manufacturers, the path into e-commerce is a relatively new venture. Traditionally, manufacturers shipped their product in bulk to stores or distribution centers. This straightforward process typically involves product in cases, loaded securely on pallets and shipped to its destination – a method which protected their merchandise fairly well.

The main difference in packaging for e-commerce is that you’re now mainly shipping individual products direct to consumers. The challenge is how to best package individual products that are secure enough to protect the contents during shipping, yet do so in an efficient and cost-effective manner. The answer can be found in automation.

Pack efficiently

For businesses that are somewhat new to e-commerce, looking to expand their presence or rely heavily on e-commerce operations, one of the best ways to be successful is to select packaging that’s as close as possible to the size of the product you’re shipping. You don’t need a large, oversized package when shipping a small item. That excess material is not necessary, and only costs you money in the end. This is what’s known as dimensional (DIM) weight.

For businesses that are somewhat new to e-commerce, looking to expand their presence or rely heavily on e-commerce operations, one of the best ways to be successful is to select packaging that’s as close as possible to the size of the product you’re shipping. You don’t need a large, oversized package when shipping a small item. That excess material is not necessary, and only costs you money in the end. This is what’s known as dimensional (DIM) weight.

DIM weight, is the amount of space a package occupies relative to its actual weight. The idea is that since most freight costs were negotiated by the pound, airlines wanted to make sure they could maximize profit by assigning a minimum weight value by volume. This means if someone is shipping a box of feathers, the carrier charges the dimensional weight instead of actual weight. The same principles apply to e-commerce shipments – since many of these are shipped via air. The more space in the package that is occupied with “air” (including packing materials, air pillows or other fillers), the greater the minimum weight of charge for the shipment. By reducing the amount of air to the size of the actual contents, the shipper minimizes the overall shipment cost.

Often companies are engineering direct-to-consumer packaging that can withstand the rigors of shipping, only to have it packaged in an oversized box that does nothing but add cost to the shipment.

These features are important because some companies do ship their products in packaging that’s generally too big or more than needed. This is typically the case with many smaller companies that follow a manual process for packing products. A common practice is to package using pre-made bags. The problem this can lead to is the pre-made bag doesn’t offer a tight, secure fit for the product, or the bag will be too large, forcing an employee to overstuff it with material. Either way, this choice does not offer a solid containment for that product. After the bag is packed, an employee needs to close and seal it, print a shipping label, and then manually attach it correctly to the bag. All of these steps are labor intensive and not very efficient with speeds limited to, on average, less than 10 packages per minute.

E-commerce technologies at work

A better option that many small-to-medium sized companies are embracing for their e-commerce operations is to automate the entire process, which can lead to significantly faster and more accurate rates than manual packing operations.

A better option that many small-to-medium sized companies are embracing for their e-commerce operations is to automate the entire process, which can lead to significantly faster and more accurate rates than manual packing operations.

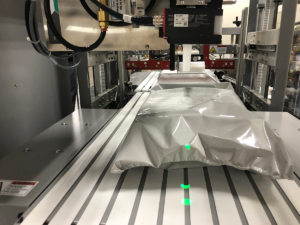

Two common automated packaging systems for e-commerce are ones that can create custom-sized flexible packaged bags around the product, or shrink-wrap products for a tight, secure seal. Clothes, blankets and other unique-sized products are ideal for flexible packaged bags; while boxed products, such as shoes, electronics, food and related items tend to be a better fit for shrink wrapping. However, both operate in a similar fashion.

Automated e-commerce packaging systems rely on a series of photo-eye tracking and verification sensors to create right-sized packaging for each individual product. During normal operation, product moves along the infeed conveyor, being tracked by photo eyes that detect the products leading edge, along with the length and position. Then, an induction camera triggers and scans the product for a unique code. The information is passed along to the customer’s warehouse management system. The system accesses the data file of addresses and cues up the correct information at the labeler.

As product advances into the wrapper and just before entering the sealer, a photo eye confirms the position of the product, and scans its length and height. Once this process is complete, the wrapper will seal and create a fully enclosed bag. The label is then applied to the bag during the seal cycle. At this point a verification camera confirms the sequence of the applied label is correct, and is ready for shipping.

One of the final benefits of using an automated system is product concealment. Many brands involved in e-commerce ship their products in logoed packaging to advertise themselves. While that makes sense for the brand, the consumer may not be that thrilled with others knowing who they purchased from. Logoed packages left outside residences loudly advertise where it’s from, which can be a target of unwanted attention.

Automating e-commerce operations can spur growth

E-commerce is certainly here to stay, and you need to be positioned to best capture your share of the growth. One way to do that is through automating your e-commerce packaging operations. Not only will you save time and money, but it will give you the flexibility to handle additional e-commerce business. Your selection and method of packaging directly impacts your bottom line.

About the Author

David Nettles is the Director of Sales at ProMach’s Shrink Systems Group. He can be reached at David.Nettles@promachbuilt.com. Learn more at www.texwrap.com