Past the Parcel: Catering to Serial Returners

New Technology Expands Packaging Reuse

By Christopher Morgan, Global Sales Director at Filtrona Tapes

For many years the life cycle of packaging has been limited to the moment of purchase, with boxes thrown away once their protective function was over. Over time, however, the significant increase in waste of all kinds – including that derived from packaging – has led to increasing public awareness of how this throw-away model is affecting the planet.

With many online retail outlets offering free standard delivery and returns, it’s easier than ever to have a change of heart after having opened the purchase. As a result, innovative returnable packaging solutions are required to meet the needs of a global circular economy – and this approach is rapidly gaining legislative support.

Do the best you can until you know better. Then when you know better, do better. Our plan, for now, is to give packaging just one more use. Working with our customers and partners, we want to bring innovations to market that help businesses expand their reuse portfolios.

Millions of shoppers, spurred on by the closure of physical stores during months of pandemic lockdowns, now regularly buy and return goods online. But sizing online is tricky; the choice is ever-expanding, and consumer preferences change at the drop of a hat.

With many online retail outlets offering free standard delivery and returns, it’s easier than ever to change your heart after trying out your purchases—the result: a wasteful merry-go-round of returned goods.

Brands, customers, and policymakers alike must now investigate this perfect storm of operational, regulatory and cultural shifts for us to achieve a future in which reusing valuable packaging materials and products becomes commonplace.

Return of the pack

Running a manufacturing operation is a difficult job. Running one that spans multiple sites and suppliers is even more difficult.

And this is even before discussing how to do it cost-effectively and efficiently.

From managing logistics and supply chains to running manufacturing equipment and processes, raw material procurement, stock management and storage, manufacturing businesses have a lot to consider – not to mention motivating and training an engaged workforce.

These hurdles can make the decision of whether to use returnable transit or single-trip packaging seem insignificant. However, getting this right can surprisingly impact your business’ manufacturing productivity, competitiveness, costs and ultimate success.

When so many retailers offer free returns, people can easily be lulled into thinking there’s no cost

attached. However, business leaders are quickly realizing that isn’t the case, with reports showing that the reverse logistics of returns cost online retailers £6.3 billion in 2020. That figure is likely to rise by 9% by 2025, according to analysts at GlobalData.

No time to waste

But it’s not just manufacturers who should consider the benefits of returnable packaging solutions, this is also a key consideration for brands in navigating the consumer journey. Consumers list the convenience of eCommerce as one of its primary benefits. It is this convenience that is one of the key drivers behind its rapid growth, which was already outpacing high-street retail even before the pandemic. With time being a commodity that today’s consumer is increasingly unwilling to waste, undermining convenience – the key value proposition for eCommerce – with a frustrating packaging experience can cripple a brand’s relationship with its consumers.

This often manifests when packaging is difficult to open. According to research commissioned by tear tape specialist Filtrona Tapes, 57% of consumers named this their top frustration stemming from packaging. Other major concerns included the recyclability of packaging as well as how easy it was to reclose and reseal, with almost 30% of respondents highlighting this as a top concern.

In any relationship, it is important that both parties feel their time is respected. This goes for the relationship between brands and their customers, too. Meeting the needs of today’s time-conscious, always-on-the-go consumer is vital for every industry, especially those relying heavily on reverse logistics such as clothing and electronics.

If a consumer needs to return a pair of jeans that don’t fit or a faulty smart gadget, this is not the end of their journey with a business. The ease of the returns process and how a company facilitates that process will continue to shape a consumer’s future relationship with that brand.

Demonstrating a pre-emptive there-if-you-need-it approach to reverse logistics by incorporating easy-return features into a packaging solution is a subtly effective way brands can enhance their packaging, turning it into a vital element of their relationship with consumers. Single-trip packaging offers none of this – its use ends when the consumer has it in their hands. Research from payment provider Klarna shows 84% of shoppers would not return to a brand following a poor returns experience, meaning it pays to remove as many roadblocks from the returns process as possible.

According to research commissioned by tear tape specialist Filtrona Tapes, 57% of consumers named difficulty opening packages as their top frustration stemming from packaging. Filtrona Tapes’ Rippatape® product line, now including the new repulpable Rippatape® Halo, opens corrugated and paper packaging cleanly, safely and without the need for tools/blades.

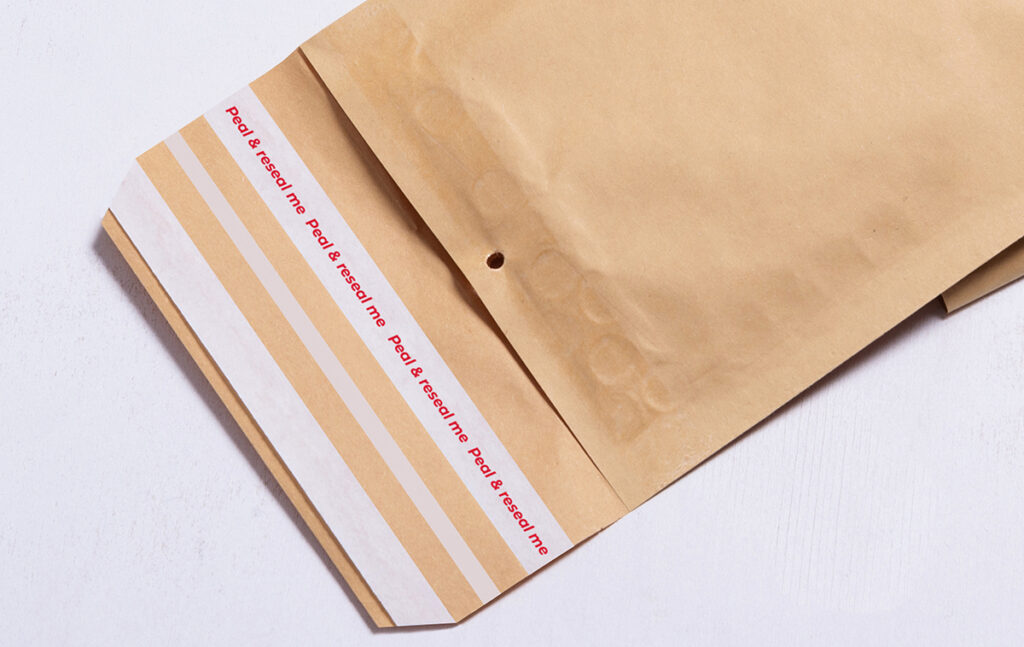

Image courtesy of Filtrona Tapes.

An open-and-shut case

As packaging solutionists, the best option is often the most straightforward one: ensuring that the packaging you deliver products in can easily be used for returns in case of customer dissatisfaction. And that was the catalyst for our latest innovations, which forward-thinking brands can use to enhance their packaging.

Incorporating an easy opening solution into returnable packaging is critical not only to improving the consumer opening experience, but it also delivers a method of opening which will maintain the structural integrity of a pack. If a consumer must destroy the packaging upon opening an item, the returns benefit is lost immediately.

Filtrona Tapes has developed the SF-AS applicator range for folder-gluer lines to enable deployment of both its Rippatape® and Easiliner for double-sided tape solutions in a single pass, and provides a range of paper-based release liners under its EASILINER banner, which protect glue lines, allowing consumers to easily remove the paper liner to reseal their packaging.

Image courtesy of Filtrona Tapes.

With the packaging opened cleanly, if returns are needed, release liners or double sided tapes offer a no-fuss, ready-to-use solution to reseal the packaging and allow hassle-free repacking for the consumer. Something as small as a glue strip and release liner can turn flexible packaging and corrugated packs into easy-return packaging with relatively little investment.

Historically, deploying both opening and closing solutions have required multiple passes through the packaging production process, but not anymore. Advances in packaging technology now mean resealing and easy opening technologies can be seamlessly woven into existing packaging lines using multi-head applicator systems.

A small price to pay

Now that the circular economy concept is firmly established, it’s clear that single-use packaging is not ideal. It places the burden of recycling on the consumer, who may need to return their purchase after disposing of its packaging, which will naturally consume more resources. And while many materials commonly used in eCommerce packaging, like corrugated cardboard, are theoretically easy to recycle, the reality is not so simple. Consumers may dispose of the packaging incorrectly or contaminate the substrate.

According to research commissioned by tear tape specialist Filtrona Tapes, the recyclability of packaging as well as how easy it is to reclose and reseal rank among consumers’ top packaging concerns. Image courtesy of Filtrona Tapes.

Returnable packaging no longer means having to accept decreases in operational efficiencies. Something as small as a tear tape and a glue strip protected by a release liner can turn flexible packaging and corrugated packs into easy-return packaging with relatively little investment.

In a hectic e-commerce environment incorporating returns features into packaging is becoming a pre-requisite for any brand looking to offer convenience, sustainability, and a high-quality experience to the consumer. Thanks to modern, intuitive applicator systems, clean opening systems, and value-adding products, returnable packaging is now more accessible for brands and converters than ever. The heyday of single-trip packaging for e-commerce applications is over – and that’s one thing that won’t be returning.

About the Author

Christopher Morgan leads Filtrona Tapes sales efforts with a truly global perspective on customers’ business needs and how to best bring innovative solutions to them.

For more information, visit https://filtrona.com/tapes.