Collaboration Unlocks Secrets to Sustainability

A Collaborative Approach to Packaging Design and Material Selections Achieves Sustainability Without Compromise

By William Kuecker, Vice President of Marketing and Chris Simmers, Vice President of Technical Services at Mondi North America Consumer Flexibles

Sustainable packaging solutions place a brand’s unique needs and environmental objectives at the heart of every project.

A key to consumer goods marketing success for the future is sustainability, and the future is now.

A case in point: according to a recent survey of buyers of pet food conducted jointly by Mondi and Dow Chemical, 75% of consumers felt more favorably towards a brand that had sustainable packaging, and 65% said they have greater trust in brands that use sustainable packaging.

While the survey focused on a single consumer market sector, it indicates a broad acceptance of sustainable products, especially among younger demographics whose consumer goods spend will grow as they become a more significant portion of the purchasing community.

And so, a question for brands to consider is: how do we best appeal to younger, sustainability-minded consumers both now and basically forever?

One answer lies in fully comprehending sustainable flexible packaging options and, with them, ways to achieve their adoption while maintaining or even improving package processing efficiencies. Recent advancements in materials engineering are making this possible. One new option is using mono films in place of polyester materials laminated to polyethylene materials; another is to custom-formulate multiple types of polyethylene resins into flexible film solutions.

It’s worth noting that even though polyethylene is a fully recyclable material, in the flexible form it is not traditionally picked up in curbside programs. Therefore, it’s essential to know if your packaging supplier has materials that are pre-approved by appropriate store drop-off programs.

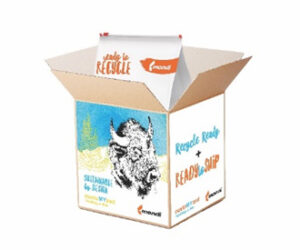

Mondi’s FlexiBag in Box is a sustainable solution designed in collaboration with customers. The ship-in-own-container (SIOC) corrugated box is paired with a recyclable flexible pouch, equipping manufacturers and retailers with a branding-through-use tool that appeals to environmentally conscious consumers shopping in stores or online. Image courtesy of Mondi.

From past to present

Historically, the packaging industry has employed laminated polyester and polyethylene film structures to meet flexible packaging needs for stiffness, color, print quality and other shelf-appeal characteristics. Unfortunately, these structures are not recyclable through traditional recycling channels.

Needs for sustainable flexible packaging inspired the industry to develop flexible packaging that delivers shelf-appeal branding within a sustainable packaging product.

Collaborative design and materials selection

Surprisingly, brands do not always have a clear set of packaging sustainability goals that are communicated throughout the organization. Their company websites typically cover the business’s dedication to sustainability and its past achievements, but clearly stated, quantifiable future packaging-related goals tend to be in the future horizon realm.

Let’s look at how brands can best collaborate with their packaging supplier to identify, balance and meet sustainability goals pertaining to issues like life cycle assessment, greenhouse gas reduction, recyclability, compostability, plastic reduction and recycled content.

To arrive at a solution that is sustainable by design, we need to question everything. This means looking at all the solutions, production processes, materials, and specifications needed to protect the product. The approach puts a brand’s unique needs and environmental objectives at the heart of every project. It begins with a discussion of what a brand needs to meet its sustainability goals and what it is not willing to compromise to achieve them.

Development and trial phase

By collaborating with Mondi, zooplus AG designed a recyclable pet food package that meets their requirements, maintains the look and feel of the high-end brand’s premium packaging and eliminates metallic substances used in the original packaging graphics. Image courtesy of Mondi.

A key part of the process is technical support provided during the development and trial phases of transitioning to sustainable materials. Technical specialists provide on-site trial support at machine suppliers and customer locations to help ensure that end users meet their sustainability goals.

Collaborative design and materials selection constitute a major shift in the packaging technology sector, one that is steadily replacing off-the-shelf, transactional solutions. It consists of a brand’s designers and sustainability teams, along with its marketing and purchasing managers, collaborating with materials experts who have the knowledge and resources to identify sustainability and processing opportunities and the equipment to capitalize on them.

Discussions between a materials expert and a brand’s management often start with a minor homework assignment for the brand, beginning with unalterable essentials. These might include minimum specs for rigidity, needs for handling components, such as easy-open or pour and top sliders in the product appeal category. In processing, the brand might have requisites to meet form/fill/seal speeds or requirements associated with filling machines.

Color, print quality and consistency are universal priorities, but a brand might have a preference for rotogravure, HD or Ultra HD flexographic printing or want matte or gloss coatings for their packages. These factors all come into play when reaching for sustainability without compromise.

Benchmarks for sustainability gains

At the same time, the brand will need to establish benchmarks for sustainability gains. For example: does it aim to increase its percentage of recyclable packaging by 50% by 2025; or increase PCR (post-consumer recycled) content in a particular product line by 25%?

While this up-front homework comes with an investment in time, it has proven to yield a greater likelihood of sustainability success and long-term market impact.

To illustrate the power of the collaborative approach, consider the case of zooplus AG, the leading European pet food online retailer that recently addressed growing demand for sustainable packaging. The retailer sought a solution for greater package recycling with no compromise on any performance attribute, including aesthetics and barrier protection against moisture and odors.

Testing package designs and materials

Testing throughout the collaborative method of package design is essential for formulating a package that meets both sustainability and processing goals. A packaging supplier’s quality management systems should incorporate vacuum bursts and creep tests to ensure air tightness in a brand’s small to large packaging and with whatever closure systems might be in place.

Other critical tests include tensile strength, dimensional measurements, coefficient of friction, drop strength, film thickness and monitoring for residual solvents.

Stiffness or rigidity testing along with resistance to stretch are especially important. A certain amount of stiffness is needed for shelf presence and appearance. It is rigidity that allows a package to stand upright on the store shelf. In addition, the tests help ensure stability in printing, laminating and other converting processes.

A parallel type of test evaluates a brand’s equipment upfront, such as its form/fill/seal machinery. Detecting and adjusting faulty equipment conditions can eliminate problems that could wreak havoc with even the most carefully formulated new packaging film. Packaging consultants might suggest certain refinements or calibrations to help achieve trouble-free processing with a new sustainable film.

Replace, reduce and recycle

A collaborative process guided by the three pillars of replace, reduce, recycle leads to the development of customized products meeting critical consumer sustainability, appearance and performance requirements. When package designs and material selections are based on collaborative partnerships with customers, packaging meets performance requirements and satisfies food manufacturers’ and retailers’ sustainability goals.

About the Authors

William Kuecker is Vice President of Marketing and Chris Simmers is Vice President of Technical Services at Mondi North America Consumer Flexibles. For more information, visit www.northamerica.mondigroup.com.