Search results for: multi-conveyor

Multi-Conveyor Sponsors Winneconne Robotics Club

… 4th and 5th graders win big! CONGRATULATIONS to the Winneconne Robotics Club’s Cody Skadahl (grade 5), Jory Bastian (grade 5), Ryker Morden (grade 4), and Sullivan McCabe (grade 4), who earned two trophies at two separate tournaments this year, the Energy Award and The Innovate Award (State Qualifier). The robotics team participated in three…

Read MoreMulti-Conveyor’s Food-Grade Slim Fit Small Product Transfer System Sets Industry Standards

The food-grade Slim-Fit is the newest line of low profile, wash down, sanitary conveyor belts from Multi-Conveyor. Featuring tool-less belt removal, the pre-engineered small product transfer conveyor is designed for tight spaces, and features 100% stainless steel, 3-ply blue wash down belting and easy tool-less belt removal. “The Slim Fit sanitary conveyor is becoming the…

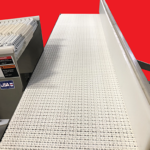

Read MoreMulti-Conveyor Quick-ship Conveyor

In addition to custom conveyor systems, Multi-Conveyor builds basic, quick-ship plastic chain conveyors by the mile. These modular systems are designed to be pieced together fast, and are available in various pre-fabricated lengths, widths or radius curves. “Although we’re a conveyor manufacturer known for our custom conveyor solutions, our standard conveyors are probably the most economical, quick-ship…

Read MoreSneak Preview: Multi-Conveyor Booth C-1718 Pack Expo Las Vegas

Multi-Conveyor will have many conveyor technologies on display at Pack Expo Las Vegas with the claim of reviewing all of them in less than 30 seconds! The theme, “give us 30 seconds”, goes hand-in-hand with our touchless “scan & go” technology downloads and our 25-second “everything we make” video. Running on the show floor will…

Read MoreThe Case for C-Grippers by Multi-Conveyor

… more flexibility, small footprint, big return. Side grip elevator conveyors, better known as “Grippers“, are designed to transport packaged goods, at customer specified elevation, from infeed to discharge, naturally reorienting the product in the process. Gripper are two parallel conveyors mounted side-by-side using neoprene bulb chains facing one another to form a gentle compression.…

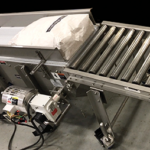

Read MoreMulti-Conveyor Builds Sectional, Ergonomic and Portable Conveyor

Multi-Conveyor recently built several conveyors specifically designed and engineered to improve ergonomics in the semi-automated transport of very heavy, powder filled and sealed paper bags of dry food. Filled and sealed upright bags require an operator to manually reposition the product to lay flat for initial transport out of a bulk bagging room. Multi-Conveyor custom…

Read MoreSneak Preview: Multi-Conveyor Booth S-3401, Pack Expo International Chicago

Multi-Conveyor will have many conveyor technologies on display at Pack Expo International with the claim of reviewing all of them in less than 30 seconds! The theme, “give us 30 seconds”, goes hand-in-hand with our touchless “scan & go” technology downloads and our 25-second “everything we make” video. Running on the show floor will be…

Read MoreSneak Preview: Multi-Conveyor Booth C-2300 Pack Expo Las Vegas

Multi-Conveyor will have many conveyor technologies on display at Pack Expo Las Vegas with the claim of reviewing all of them in less than 30 seconds. The theme, “give us 30 seconds”, goes hand-in-hand with the company’s touchless “scan & go” technology downloads and its 25-second “everything we make” video. Running on the show floor…

Read MoreMulti-Conveyor Receives Consecutive ACUITY Insurance Safety Achievement Award

Multi-Conveyor LLC was presented with the ACUITY Safety Award for businesses that exemplify the partnership with ACUITY that helps ensure a safe workplace. The plaque was presented by Chad Kaster, Loss Control Representative at ACUITY, to Joe Miller, COO, Multi-Conveyor. According to ACUITY, only a handful of its manufacturing customers quality for this award due…

Read MoreVertical 2-to-1 Bag Inject Conveyor: Multi-Conveyor LLC

Multi-Conveyor recently built a stainless steel constructed 2:1 vertical merge conveyor designed to transport individual bags of frozen food.

Read MorePerfectly Timed First-in, First out 2-to-1 Merge Conveyor: Multi-Conveyor

Multi-Conveyor recently built a sanitary stainless steel welded, plastic belt conveyor to merge plastic wrapped bulk cheese using brand new FIFO (first-in, first-out) technology.

Read MoreGripper Side Grip Elevation Conveyor: Multi-Conveyor

Multi-Conveyor recently built a mild steel, S-style, side grip elevator – or Gripper.

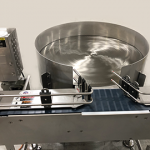

Read MoreMulti-Conveyor Builds Conveyor for Bottle Capper Rejects

WINNECONNE, WI | Multi-Conveyor recently built a series of stainless steel, mostly washdown constructed conveyors for a bottle capper reject application. A 42″ long straight running table top chain conveyor was built to accept rejected bottles of a liquid food product that will be dispensed onto a 36″ stainless steel rotary accumulation table. The accepting tabletop…

Read MoreMulti-Conveyor

Multi-Conveyor partners with OEM’s, design firms, integrators and engineering experts to produce some of the most revered conveying systems in existence. Our designers put new ideas in motion daily. Each week we strive to improve department efficiencies; each month we review equipment to build a better, more cost-effective product. That proficiency translates to quality, reliability and savings to our customers.

Read MoreStart-up Distillery uses Mass-Flow, Reflow & Single Lane Accumulation

… including full transport conveyance from pasteurizer to case packer. Multi-Conveyor was recently requested to build a series of conveyors to transport and accumulate a ‘bourbon shine’ inspired beverage for a start-up distillery in the Smokey Mountain foothills. A variety of conveyor technologies were implemented to smoothly transport beverage cans between different processing machines in…

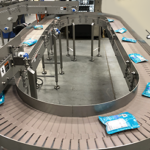

Read MoreRacetrack Accumulation Feeds Hand Pack Operation

… sounds like an oxymoron, but it’s not. Multi-Conveyor recently built a series of conveyor technologies designed to tactically transport a granulated or whole bean dry beverage product. Product travels from two bagger discharges, though curves and elevations, ultimately depositing onto a continuous running loop where it is staged for hand-packing. (Note: Product used in…

Read MoreConveyors with Varying Sanitation Levels Make Sense, and Impact the Bottom Line

Multi-Conveyor recently built a food-grade transport conveyor system consisting of two levels of sanitary compliance. The initial conveyors are stainless steel constructed for maximum 3A Dairy compliance as required to move processed cheese in a food-grade, wash-down atmosphere through the bagging process. The filled bags then travel through a sectional wall, into a reduced sanitation…

Read MoreExhibit Sales Open for PACK EXPO Southeast 2025

Newest show from producer PMMI targets untapped, robust manufacturing region for spring 2025 debut in Atlanta Packaging and processing companies seeking to share their latest machinery, materials, and innovations with the growing manufacturing industry in the southeast, can now sign up to exhibit at PACK EXPO Southeast, which will debut in spring 2025 in Atlanta…

Read MoreMobile Bottling Conveyor Engineered to Fit in a Trailer

… from vineyard to packed cases of wine. Multi-Conveyor was approached by a reputable wine industry integrator in search of complex conveyor engineering. Our team of decades-experienced engineers were the only conveyor manufacturer willing to take on that challenge – and it paid off. This is the second of two mobile bottling lines for the…

Read MorePACK EXPO Returns to Las Vegas

PMMI Prepares for Largest Show Since Its Inception Produced by PMMI, The Association for Packaging and Processing Technologies, PACK EXPO Las Vegas will feature more than 2,000 suppliers, spanning nearly 1 million square feet of exhibit space from Sept. 11–13 at the Las Vegas Convention Center. To learn more about PACK EXPO Las Vegas or…

Read More