|

||

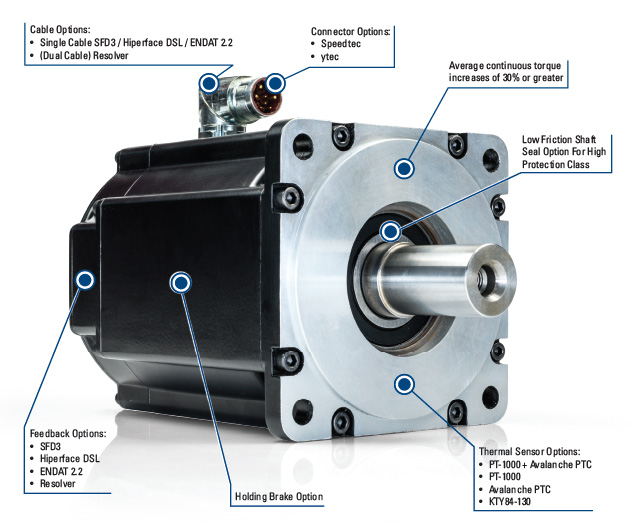

AKM®2G represents the latest evolution of the industry leading AKM motor product family. With average continuous torque increases of 30%, OEMs and users can achieve substantial machine performance increases without increasing the size of the motor. The improved torque density allows a smaller motor to be used which reduces the machine footprint without sacrificing performance. |

AKM2G motors are optimized for use with the Kollmorgen AKD® Servo Drive and the forthcoming AKD® 2G family of new generation servo drives, but are also capable of providing all their design benefits in conjunction with the customer’s choice of servo drives. |

|

More from Packaging Technology Today

New Website Features Bosch’s Entire Cartoning and Case Packing Portfolio

Bosch Packaging Technology announced a new online information platform. The new website showcases Bosch’s cartoning and case packaging solutions. The objective was to create a website with a user-friendly design and easy navigation, in order to get a quick portfolio overview, and find a machine for every need. The website replaces the Kliklok-Woodman and Kliklok International websites and complements Bosch’s existing cartoning and case packing portfolio. Read MoreTauber-Arons To Auction Vast Array Of Top Quality Warehouse Support Equipment From Avon’s Cosmetic Packaging and Distribution Facility In Pasadena

Tauber-Arons of Los Angeles is pleased to announce that recently Avon came calling, looking for an auctioneer with the foundation to handle the complete liquidation of their packaging and distribution facility in Pasadena, California. Read MoreContinuous Inkjet Considerations for Budget Conscious Manufacturers

When budgets are tight, and operating margins are thin, manufacturers tend to get creative when sourcing coding equipment. Some common practices include buying used equipment sight-unseen, purchasing “low cost” coders from foreign suppliers, and even unknowingly resorting to paying more in parts and labor to keep a printer running than simply purchasing a new coder. Read More

| About Us | Subscribe | Buyers Guide | Advertise |